Copyright © 2024 ZHONGSHAN LIKE SILICONE PRODUCT CO.,LTD. All rights reserved.

- No. 32, Jianye Road, Torch Development Zone, Zhongshan, Guangdong Province.

Once the order is confirmed, we will provide a DFM report and review all tolerances and cosmetic specification etc, the engineer will point out any issues that may affect the quality of your parts.

Firstly, all incoming materials will be inspected. COA (Certificate of Analysis) of raw plastic material from our supplier would be provided.

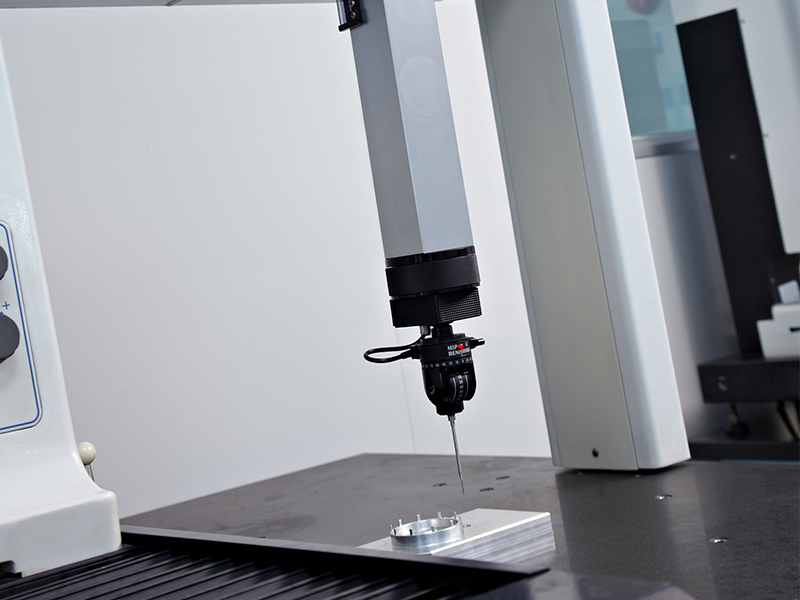

After T1 samples, we will providefull dimensions inspection report.

During the manufacutring process, our project engineer will double check the parts in terms of size, tolerance, and appearance.

Provide the quality inspection report before shipment.

Extract a sample of 11 cm, approximately 10 grams, and place it in a drying oven. After drying for 48 hours, weigh the sample (value A). Note: For Germany, the sample size is 12 cm.

Then, place the sample in an oven at 200±5°C for 4 hours. Afterward, dry the sample in the drying oven for 4 hours, and then weigh the sample (weight B).

VOM content calculation: (A−B)/A×100%(A – B) / A \times 100\%(A−B)/A×100%

Contact Us

If you are interested, please feel free to contact us. We will provide you with professional answers as soon as possible.

No. 32, Jianye Road, Torch Development Zone, Zhongshan, Guangdong Province.

+86 0760-88502258

Forging a globally leading enterprise in liquid silicone molding technology solutions.

Copyright © 2024 ZHONGSHAN LIKE SILICONE PRODUCT CO.,LTD. All rights reserved.